Монтажна челична конструкција зграде, челична конструкција, школска канцеларија, складиште

Већина равних кровова ниских вила су коси кровови, тако да је конструкција равног крова углавном управљана троугластим порталним челичним оквирним системом направљеним од хладно вучених челичних компоненти. Лаке челичне конструкционе компоненте су заптивене структурним панелима. Након сакупљања гипсаних плоча, формиран је веома стабилан „ребрасти структурни систем“. Овај структурни систем има јачу сеизмичку отпорност зграде и способност да се одупре хоризонталним оптерећењима, и може се користити у подручјима са нивоом сеизмичке отпорности зграде од 9 степени или више.

Ефекат звучне изолације је важан показатељ за идентификацију куће. Прозори уграђени у светлостЧелична зграда 40x60Систем је направљен од двослојног изолационог стакла. Ефекат звучне изолације је посебно добар, са звучном изолацијом која достиже више од 40 нивоа звука. Зидови су преграђени лаким челичним кобилицама и топлотном изолацијом. Зид је направљен од сирових гипсаних плоча, а његов ефекат звучне изолације може достићи 60 звучних таласа.

*Пошаљите имејл на[заштићена имејл адреса]да бисте добили понуду за ваше пројекте

| Назив производа: | Метална конструкција челичне зграде |

| Материјал: | Q235B, Q345B |

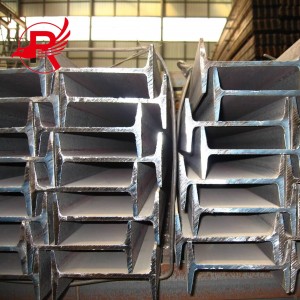

| Главни оквир: | Челична греда у облику слова Х |

| Греда: | Челична греда облика C, Z |

| Кров и зид: | 1. валовити челични лим; 2. сендвич панели од камене вуне; 3. ЕПС сендвич панели; 4. сендвич панели од стаклене вуне |

| Врата: | 1. Роло капија 2. Клизна врата |

| Прозор: | ПВЦ челик или легура алуминијума |

| Доњи излив: | Округла ПВЦ цев |

| Примена: | Све врсте индустријских радионица, складишта, високих зграда |

Детаљи производа

ПРЕДНОСТ

Нестабилност притиска се генерално јавља изненада и веома је деструктивна, тако да притискач мора имати довољну стабилност.

Укратко, да би се осигурао безбедан и поуздан рад челичних елемената, елементи морају имати довољну носивост, односно довољну чврстоћу, крутост и стабилност, што су три основна захтева за обезбеђивање безбедног рада компоненти.

Израда метала је стварање металних конструкција процесима сечења, савијања и склапања. То је процес са додатом вредношћу који укључује стварање машина, делова и структура од различитих сировина.

Израда метала обично почиње цртежима са прецизним димензијама и спецификацијама. Израђивачке радионице запошљавају извођачи радова, произвођачи оригиналне опреме (OEM) и произвођачи добављача вредности (VAR). Типични пројекти укључују лабаве делове, структурне оквире за зграде и тешку опрему, као и степенице и ограде.

Квалитет конструкционог челика

Постоји много различитих избора када је у питању конструкциони челик. Што је нижи садржај угљеника у изабраном челику, то је лакше заваривати. Нижи садржај угљеника значи бржу производњу на грађевинским пројектима, али такође може отежати обраду материјала. FAMOUS је у могућности да понуди решења за конструкциони челик која су ефикасно направљена и веома ефикасна. Радићемо за вас како бисмо одредили савршен тип конструкционог челика за ваш пројекат. Процеси који се користе за пројектовање конструкционог челика могу променити трошкове. Међутим, конструкциони челик је исплатив материјал када се правилно користи. Челик је одличан, веома одржив материјал, али је далеко више...

Ако желите да изградите школску зграду, индустријски објекат или складиште челичних конструкција, избор...произвођач школских зграда са челичним конструкцијама на великоје неопходно. Ројал Груп обезбеђује све материјале за челичне конструкције и гарантује висок квалитет и чврстоћу.

ДЕПОЗИТ

Имена и функције сваке компонентеМеталне зграде по мери:

1. Основе

Односи се на носиву компоненту на дну зграде која је у контакту са темељима, и доњи продужетак конструкције који је у директном контакту са темељима ради преношења оптерећења. Његова функција је да пренесе терет са горњег дела зграде на темеље. Стога темељ мора бити јак, стабилан и поуздан. Неке структурне компоненте испод земље инжењерских објеката користе се за пренос терета горње конструкције на темеље.

2. Уграђени делови

Генерално, приликом изградње грађевинских радова или постављања темеља, како би се олакшала поставка конструкције на темељ или погодност касније постављања опреме, прво се постављају неке основе за опрему, или анкерни вијци, или помоћне челичне плоче итд. Након што је темељ завршен, накнадна опрема се може лако причврстити на уграђене панеле или уграђене делове. Ово је веома уобичајено у инжењерству.

3. Стубови

Вертикални елементи у инжењерским конструкцијама који углавном носе притисак, а понекад и моменте савијања, користе се за ослањање греда, решетки, подова итд. Облици попречног пресека се класификују на квадратне стубове, цилиндре, цевасте стубове, правоугаоне стубове, стубове у облику слова I, стубове у облику слова H, стубове у облику слова T, стубове у облику слова L, стубове у облику крста, стубове са два крака и решеткасте стубове; стубови су изузетно важни у конструкцији. Квар неких стубова довешће до оштећења и урушавања целе конструкције.

Независни стубови су стубови који носе терет надградње зграде. Структурни стубови су стубови који побољшавају структурну стабилност зида зграде. Забатни стубови отпорни на ветар, као што име сугерише, углавном играју улогу у отпорности на ветар, али имају и улогу антивибрације и јачања стабилности. Пошто је забатни зид направљен од једноделног зида, који је превисок, користи се за побољшање стабилности и отпорност на оптерећења ветром/земљотресом како би се спречила нестабилност забатног зида. И оквирни стубови и независни стубови су компресионе структурне стубове који играју улогу носивости. Оквирни стубови се користе у оквирним конструкцијама или локалним. Носиви структурни стубови оквирне конструкције су повезани заједно преко оквирних греда и континуираних греда како би функционисали заједно.

ПРОЈЕКАТ

Произвођачи челичних зградачесто извози производе од челичних конструкција у Америку и земље Југоисточне Азије. Учествовали смо у једном од пројеката у Америци са укупном површином од приближно 543.000 квадратних метара и укупном потрошњом од приближно 20.000 тона челика. Након завршетка пројекта, постаће комплекс челичних конструкција који интегрише производњу, живот, канцеларије, образовање и туризам.

ИНСПЕКЦИЈА ПРОИЗВОДА

Извођење грађевинских радова смањује загађење ваздуха изазвано отпадом у еколошкој средини. СировинеЗграда од челика по мерикуће се може 100% рециклирати, а већина сировина осталих услужних објеката такође се може рециклирати, што је у складу са данашњом еколошком свешћу; све сировине су зелене и енергетски штедљиве зграде. Узимајући у обзир захтеве за управљање еколошким животном средином, корисно је за физичко здравље.

ПРИЈАВА

СветлоИзградња металних конструкцијаСтамбена структура је у потпуности састављена од хладно вучених дебелозидних челичних компоненти. Анкери су направљени од хладно ваљаних поцинкованих лимова веома отпорних на корозију и високе жилавости, што ефикасно спречава ризик од корозије лимова од угљеничног челика током процеса изградње и примене. Побољшава век трајања лаких челичних конструкцијских компоненти. Век трајања конструкције је 100 година.

ПАКОВАЊЕ И ДОСТАВА

Лака челична конструкција стамбене зграде је у потпуности састављена од хладно вучених дебелозидних челичних компоненти. Анкери су направљени од хладно ваљаних поцинкованих лимова веома отпорних на корозију и високе жилавости, што ефикасно спречава ризик од корозије лимова од угљеничног челика током процеса изградње и примене. Побољшава век трајања лаких челичних конструкцијских компоненти. Век трајања конструкције је 100 година.

СНАГА КОМПАНИЈЕ

Произведено у Кини, првокласна услуга, врхунски квалитет, светски познато

1. Ефекат обима: Наша компанија има велики ланац снабдевања и велику фабрику челика, постижући ефекте обима у транспорту и набавци и постајући челична компанија која интегрише производњу и услуге

2. Разноликост производа: Разноликост производа, било који челик који желите можете купити од нас, углавном се бави челичним конструкцијама, челичним шинама, челичним шиповима, фотонапонским носачима, каналским челиком, силицијумским челичним калемовима и другим производима, што га чини флексибилнијим. Изаберите жељени тип производа да бисте задовољили различите потребе.

3. Стабилно снабдевање: Стабилнија производна линија и ланац снабдевања могу обезбедити поузданије снабдевање. Ово је посебно важно за купце којима су потребне велике количине челика.

4. Утицај бренда: Имају већи утицај бренда и веће тржиште

5. Услуга: Велика челична компанија која интегрише прилагођавање, транспорт и производњу

6. Конкурентност цена: разумна цена

*Пошаљите имејл на[заштићена имејл адреса]да бисте добили понуду за ваше пројекте

ПОСЕТА КУПЦА